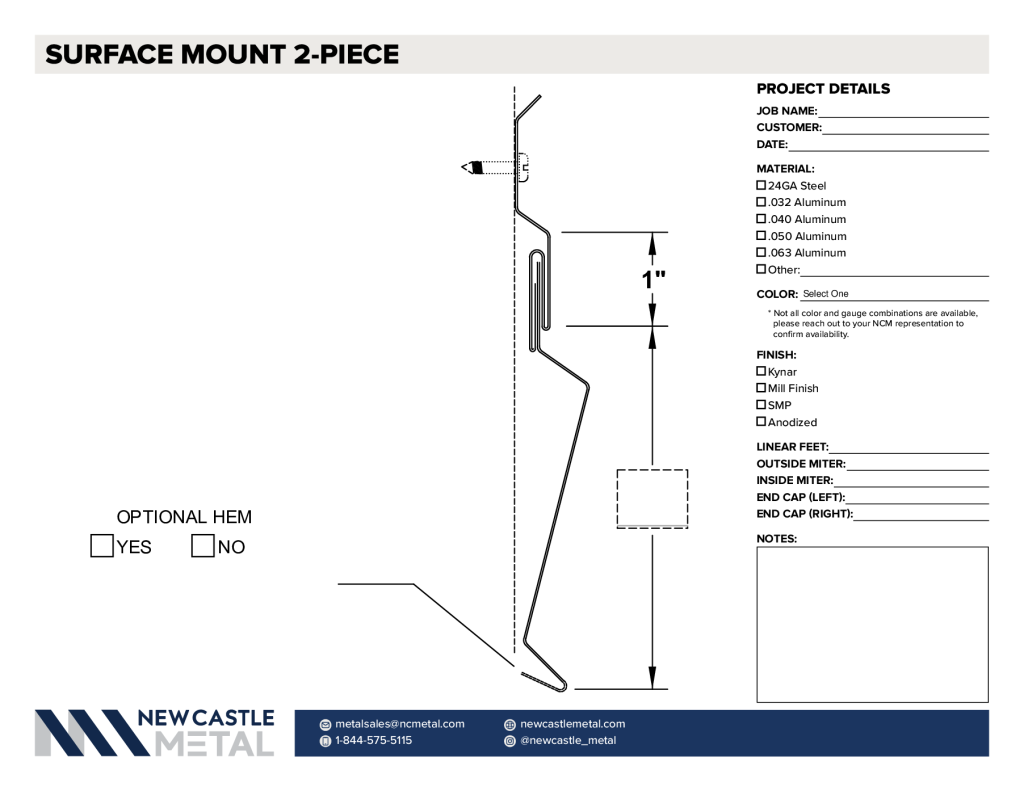

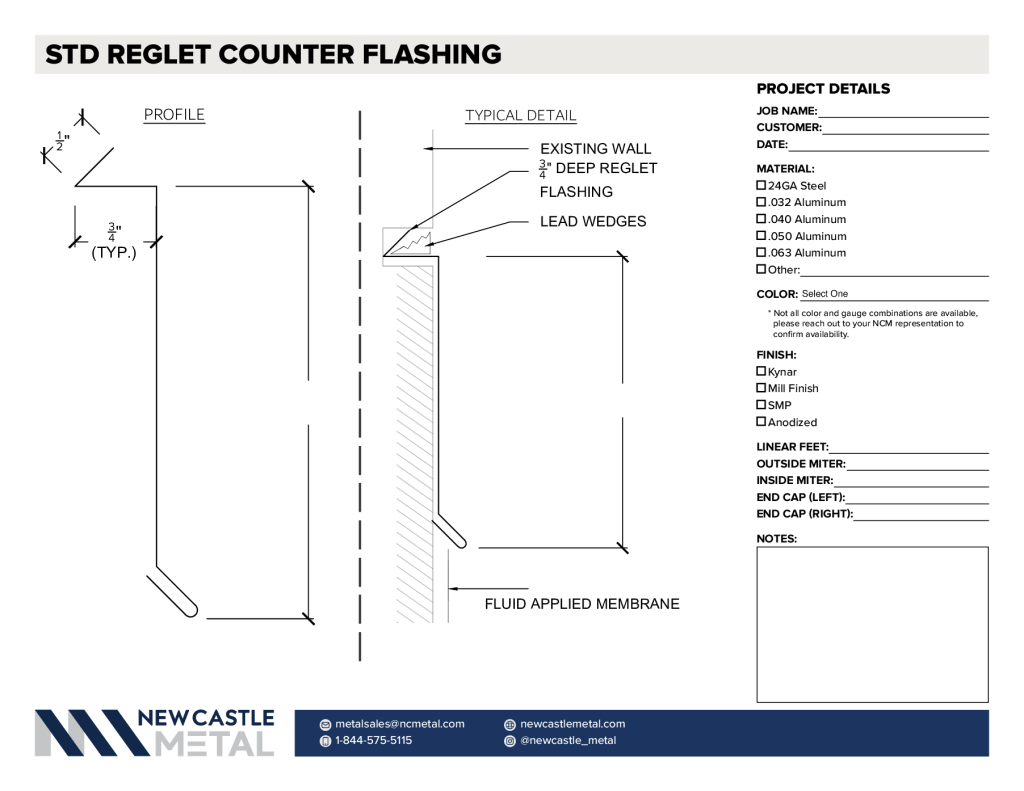

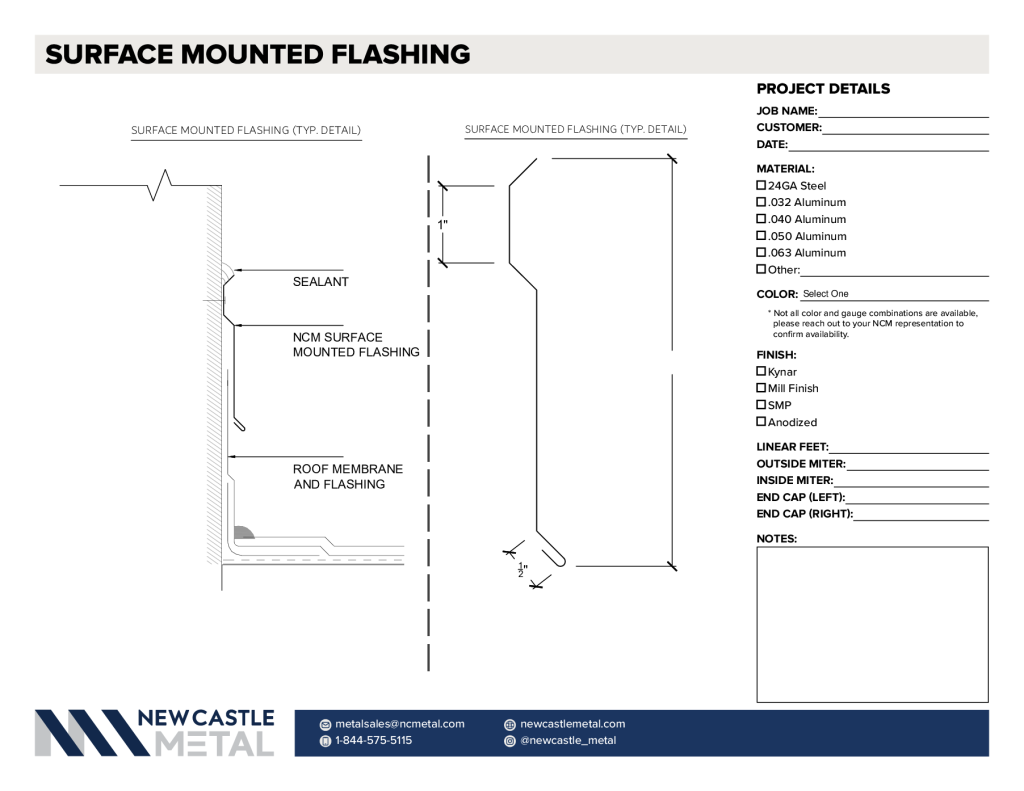

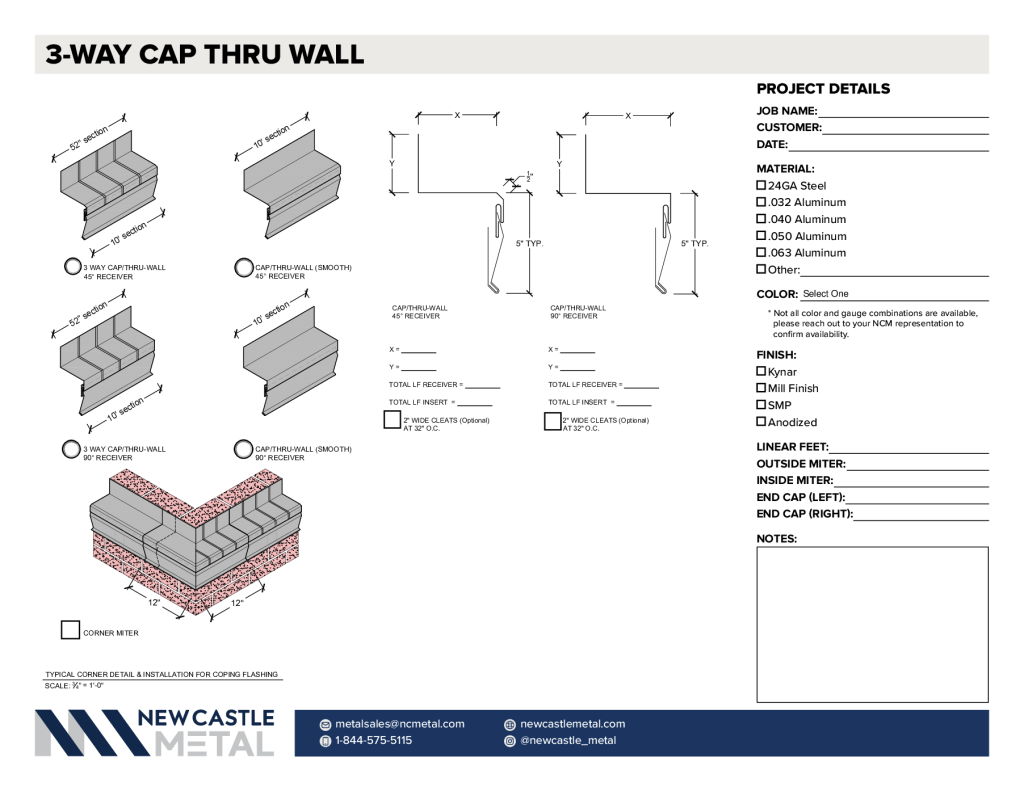

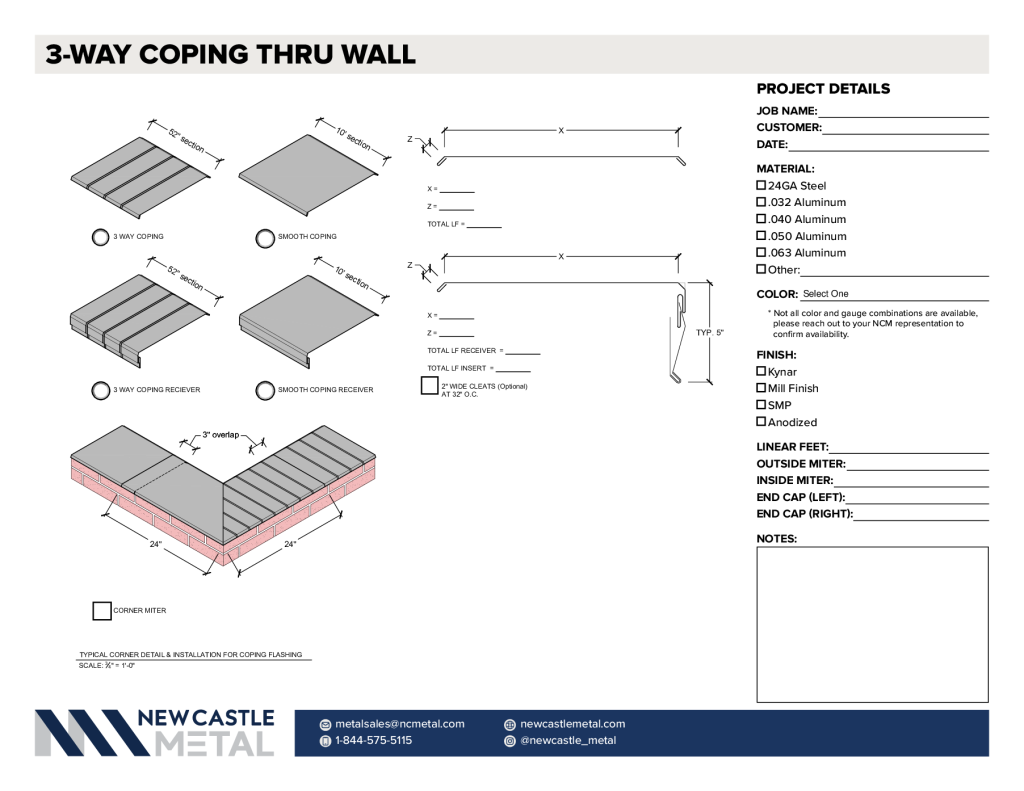

New Castle Metal’s masonry flashings are precision-engineered to form a watertight seal where low-slope roofs meet masonry walls, protecting your structure from moisture intrusion while maintaining full wall integrity. Ideal for both new construction and retrofit projects, our flashings offer robust, code-compliant protection right at those critical roof-wall junctions. They’re designed to accommodate thermal movement and support maintenance access, ensuring long-term reliability without sacrificing wall aesthetics or structural performance. Each flashing system is custom-fabricated to your project’s dimensions, enabling streamlined installation, minimizing field adjustments, and delivering a professional, clean finish. Choose from a variety of profile options, such as base flashings, counter flashings, reglets, and termination bars, all tailored to architectural needs across commercial, industrial, and institutional sectors. Thanks to New Castle Metal’s strategically located Northeast facilities - in Hicksville and Long Island City, NY; Norwalk, CT; Mountainside, NJ; Bensalem, PA; and Baltimore, MD - you benefit from quick lead times, localized fabrication, and dependable delivery. At New Castle Metal, we appreciate the importance of every joint, every flashing, and every detail when it comes to safeguarding building envelopes. Contact your nearest location today to engineer the perfect flashing fit for your next project.